A stepper motor system consists of three basic elements, often combined with some type of user interface (host computer, PLC or dumb terminal):

Indexers

The indexer (or controller) is a microprocessor capable of generating step pulses and direction signals for the drive. In addition, the indexer is typically required to perform many other sophisticated command functions.

Drives

The drive (or amplifier) converts the indexer command signals into the power necessary to energize the motor windings. There are numerous types of drives, with different voltage and current ratings and construction technology. Not all drives are suitable to run all motors, so when designing a motion control system the drive selection process is critical.

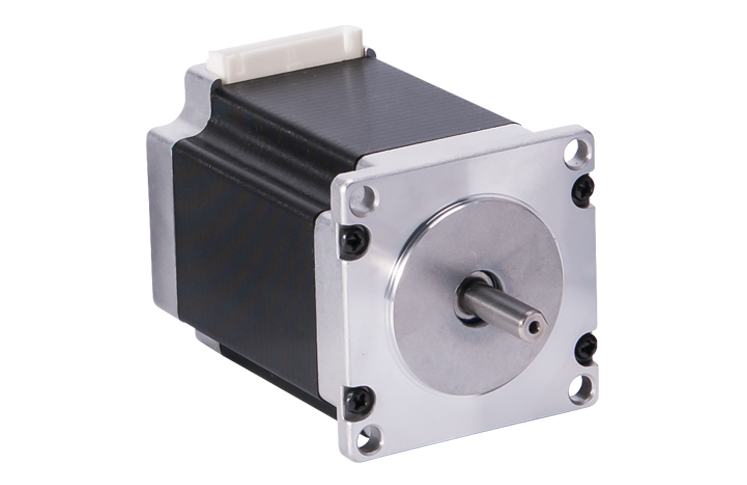

Stepper motors

The stepper motor is an electromagnetic device that converts digital pulses into mechanical shaft rotation. Advantages of step motors are low cost, high reliability, high torque at low speeds and a simple, rugged construction that operates in almost any environment. The main disadvantages in using a stepper motor is the resonance effect often exhibited at low speeds and decreasing torque with increasing speed.

Advantages of stepper motors are as follow:

l Low cost for control achieved

l High torque at startup and low speeds

l Ruggedness

l Simplicity of construction

l Can operate in an open loop control system

l Low maintenance

l Less likely to stall or slip

l Will work in any environment

l Can be used in robotics in a wide scale.

l High reliability

l The rotation angle of the motor is proportional to the input pulse.

l The motor has full torque at standstill (if the windings are energized)

l Precise positioning and repeatability of movement since good stepper motors have an accuracy of 3 – 5% of a step and this error is non-cumulative.

l Excellent response to starting/stopping/reversing.

l Very reliable since there are no contact brushes in the motor. Therefore, the life of the motor is simply dependent on the life of the bearing.

l The motors response to digital input pulses provides open-loop control, making the motor simpler and less costly to control.

l It is possible to achieve very low-speed synchronous rotation with a load that is directly coupled to the shaft.

l A wide range of rotational speeds can be realized as the speed is proportional to the frequency of the input pulses.

Computer controlled stepper motors are a type of motion-control positioning system. They are typically digitally controlled as part of an open loop system for use in holding or positioning applications.

| Tel: | +86 755 86142288-76136 |

| Hot Line: | +86-400-033-0069 |

| Head Office: | 16th Floor, Block B, Building 6, Shenzhen International Innovation Valley, Dashi 1st Road, Xili Street, Nanshan District, Shenzhen |

| R&D Center: | 16th Floor, Block B, Building 6, Shenzhen International Innovation Valley, Dashi 1st Road, Xili Street, Nanshan District, Shenzhen |