A stepper motor is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can then be commanded to move and hold at one of these steps without any feedback sensor (an open-loop controller), as long as the motor is carefully sized to the application in respect to torque and speed.

The stepper motor is known by its property to convert a train of input pulses (typically square wave pulses) into a precisely defined increment in the shaft position. Each pulse moves the shaft through a fixed angle.

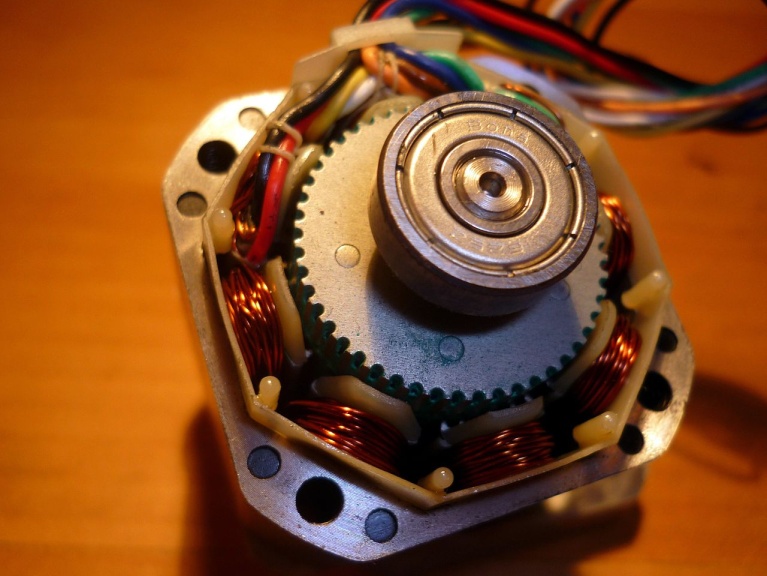

There are three main types of stepper motors: permanent magnet stepper, hybrid synchronous stepper and variable reluctance stepper.

Stepper motors' nameplates typically give only the winding current and occasionally the voltage and winding resistance. The rated voltage will produce the rated winding current at DC: but this is mostly a meaningless rating, as all modern drives are current limiting and the drive voltages greatly exceed the motor rated voltage.

A stepper's low speed torque will vary directly with current. How quickly the torque falls off at faster speeds depends on the winding inductance and the drive circuitry it is attached to, especially the driving voltage. Stepper motors do not offer as much torque or holding force as comparable DC servo motors or DC gear motors. Their advantage over these motors is one of positional control. Whereas DC motors require a closed loop feedback mechanism, as well as support circuitry to drive them, a stepper motor has positional control by its nature of rotation via fractional increments.

Steppers should be sized according to published torque curve, which is specified by the manufacturer at particular drive voltages or using their own drive circuitry. Step motors adapted to harsh environments are often referred to as IP65 rated.

The US National Electrical Manufacturers Association (NEMA) standardizes various aspects of stepper motors. They are typically referred with NEMA DD, where DD is the diameter of the faceplate in inches × 10 (e.g., NEMA 17 has diameter of 1.7 inches). There are further specifies to describe stepper motors, and such details may be found in the ICS 16-2001 standard.